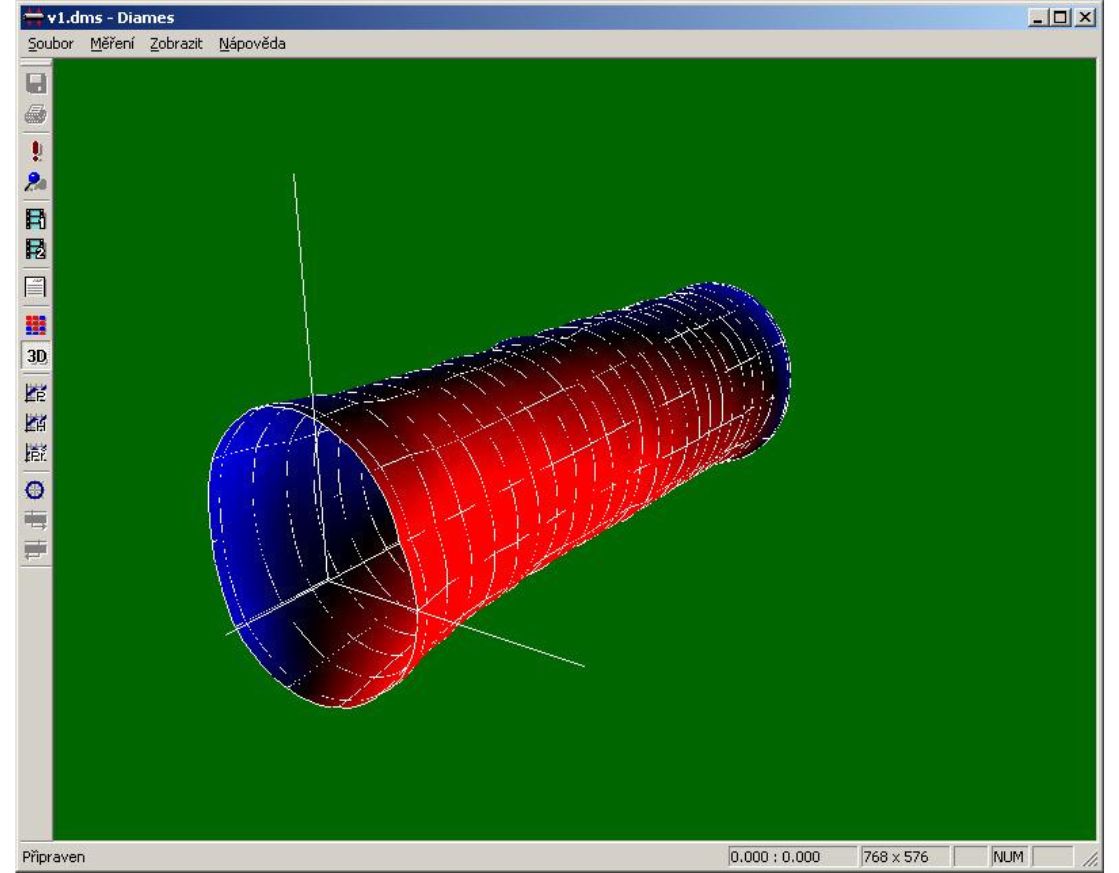

Cylinder measurement and control

Measuring stations used for contactless 3D measurement of cylindrical parts.

The system can be used in any production or printing workshop or industrial production where the correct dimension of the product in the form of a cylinder has to be checked.

The system is based on profile measurement method in backlight illumination and allows you to quickly and efficiently evaluate the 3D parameters measured to ensure the quality of the production process.

The control device can be tailored to specific customer requirements, including system extensions that look for surface defects. It offers the possibility of evaluating and displaying deviations from the ideal shape in a drawing in CAD format.

The solution also includes SW equipment and a calibration product. Thanks to the unique measurement and calibration method, measuring accuracy can be up to ± 0.02mm. The device is designed to be placed in a clean workshop or in a manufacturing facility.

| Parameter | Value | Unit |

|---|---|---|

| Minimum cylinder diameter | 2 | mm |

| Maximum cylinder diameter | 500 | mm |

| Maximum cylinder length | 1500 | mm |

| Ambient temperature | 5 – 35 | °C |

| Measurement accuracy | from ± 0,03 | mm |

| Measurement time | < 60 | s |

| Power supply | 230 | V |

| Communication interface | Ethernet | – |

| Data archiving | Yes | – |

| Connection with the superior system of the production line possible | Yes | – |

| Comparison with CAD drawing | Yes | – |