Inspection of extremely hot products

Our solution for automated optical inspection is a camera system designed for contactless measurement and control of hot objects, especially glass products and semi-finished products at a temperature of up to 1400 °C.

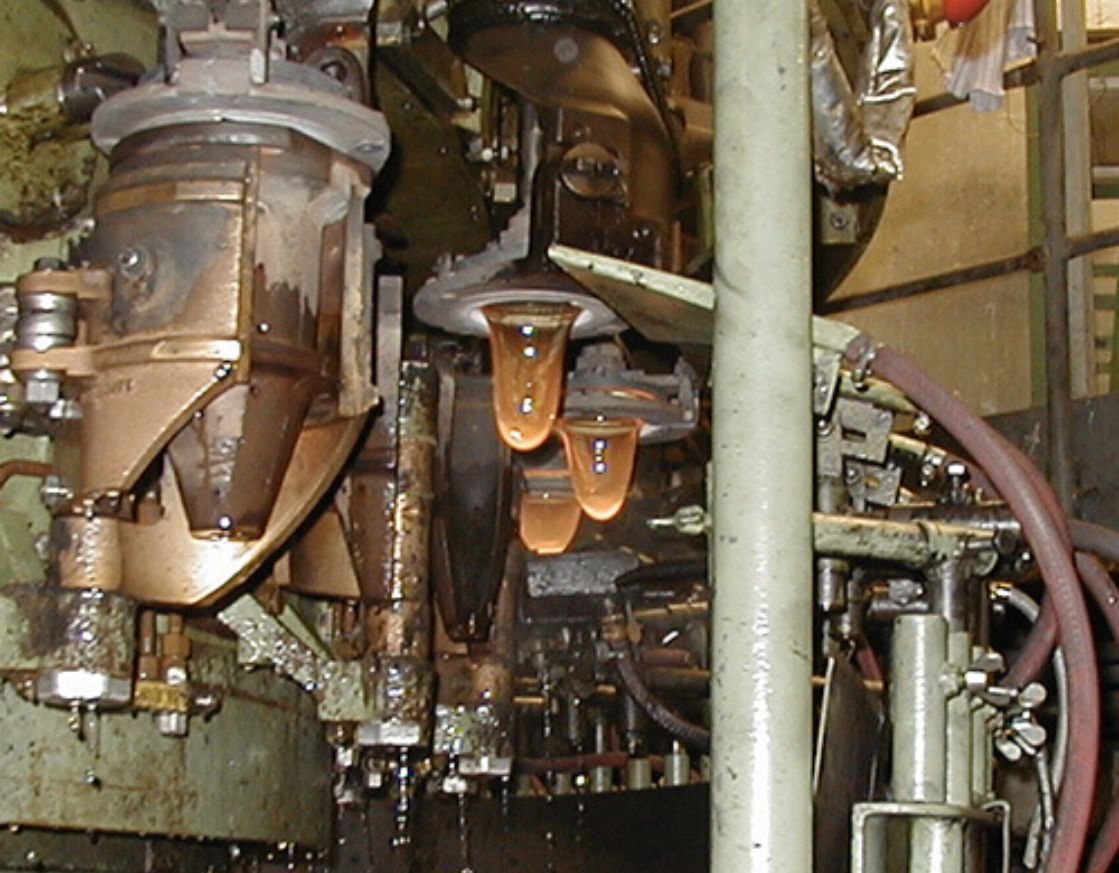

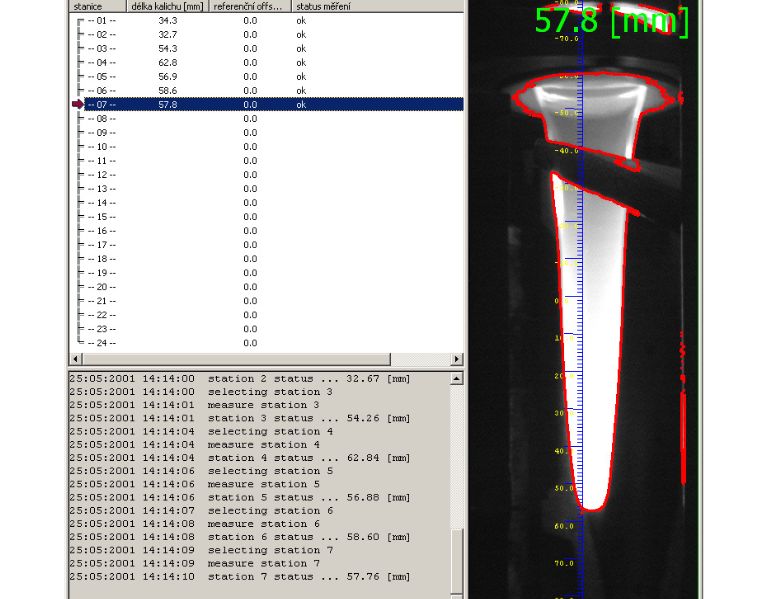

An example is a system for measuring the length of a glass drop in the production of beverage glasses. The glass drop is flattened and filled with compressed air. The length of the droplet is controlled by air and gravity pressure, and its length is measured by a camera. The measured length is used to adjust the air pressure and other parameters of the production line. The camera system is designed to operate in a hazardous environment of glassworks.

| Parameter | Value | Unit |

|---|---|---|

| Minimum product dimension | 15 | mm |

| Maximum product dimension | 1000 | mm |

| Product temperature | 500 až 1400 | °C |

| Measuremet accuracy | from ± 0,05 | mm |

| Measuring time | < 1 | s |

| Communication interface | Ethernet | – |

| Data archiving | Yes | – |

| Connection with the superior system | Yes | – |