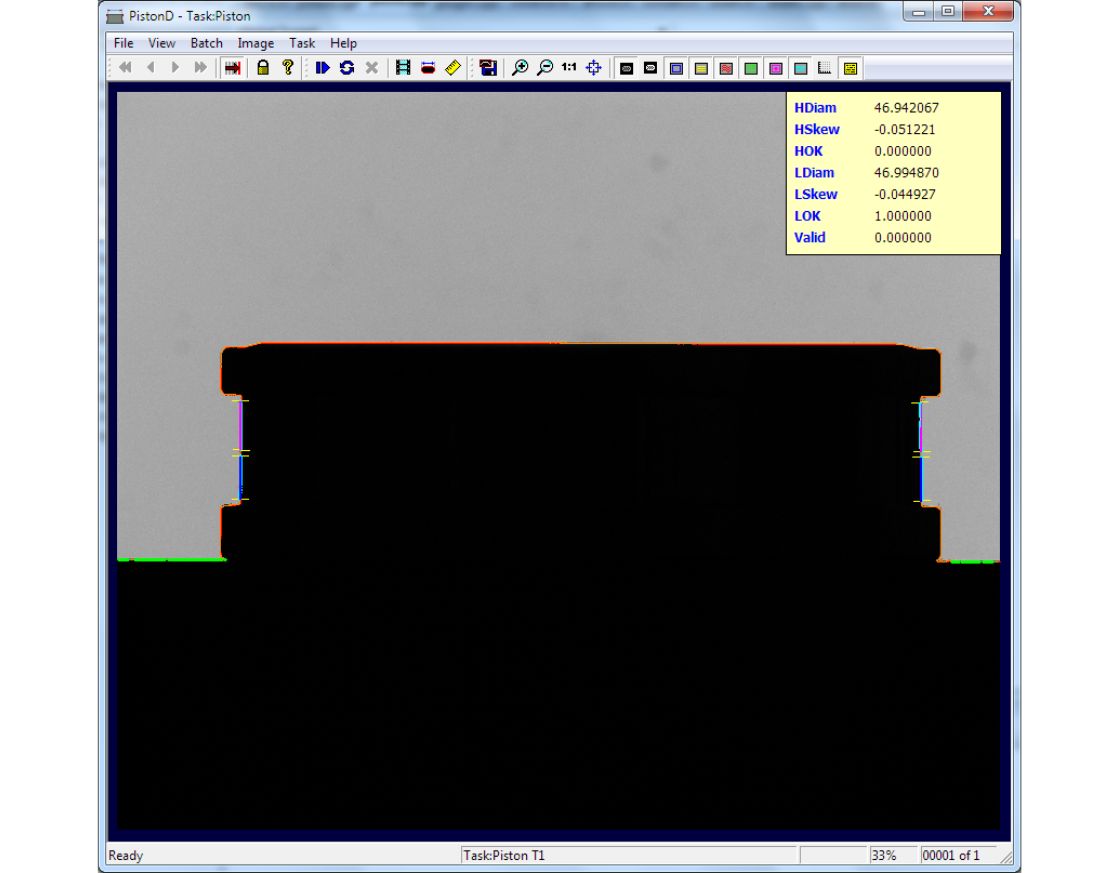

Profile measurement in backlight illumination

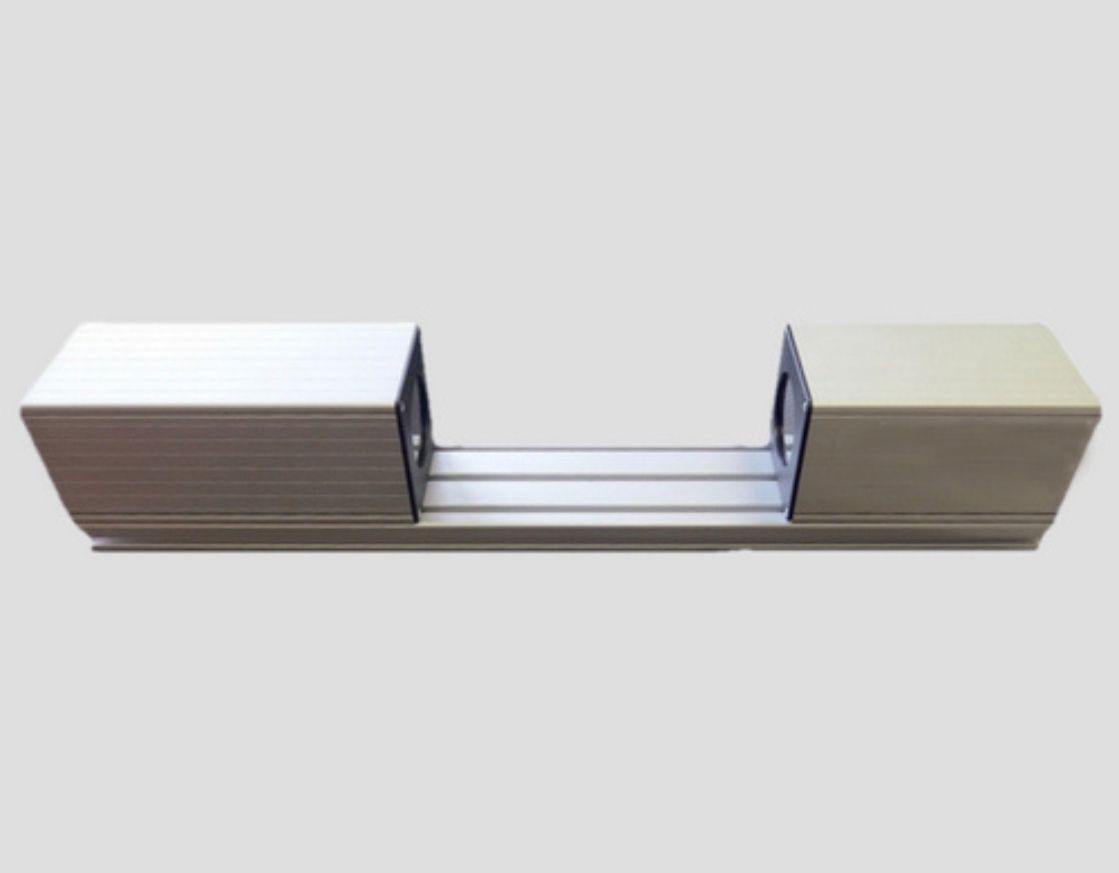

OpaSol is a measuring station used for contactless measurement of dimensions of components.

The system can be used in any workshop or industrial production where various bolts, shafts, pins or other rotary products or tools must be inspected.

OpaSol is based on a profile measurement method and allows you to quickly and efficiently evaluate measured parameters to ensure the quality of the production process. Measuring devices can be tailored to specific customer requirements. It offers the possibility of evaluating and displaying deviations from the ideal shape in a drawing in CAD format. Additionally, it is possible to adapt the prism for storing the product in a particular shape.

The solution also includes SW equipment and a calibration product. Thanks to the advanced calibration method, measuring accuracy can be up to ± 1 μm.

The measuring device is designed to be placed in an office or a production facility. A simple, yet robust device that, thanks to the built-in grooves on its side, can also be attached in a non-gravity position or anchored directly to the machining centre. With its simple robotic arm that pulls out the products from the machining centre, inserts them into the measuring station and immediately sorts the identical and non-conforming products, it performs a coherent chain of operations that minimizes operator demands.

| Parameter | Value | Unit |

|---|---|---|

| Minimum product size | 2×2 | mm |

| Maximum product size | 60×40 | mm |

| Ambient temperature | 5 – 35 | °C |

| Measurement accuracy | from ± 0,001 | mm |

| Measurement time | <1 | s |

| Power supply | 24/230 | V |

| Communication interface | Ethernet | – |

| Data archiving | Yes | – |

| Connection with the superior system of the production line possible | Yes | – |

| Comparison with CAD drawing | Yes | – |